Zenith 601 XL-B Build Project Status Update

By Kelvin Downs, EAA 1305615, VP of Chapter 1410, High River, Alberta

March 2020 - A journey of a thousand miles begins with a single step. — Lao Tzu

Success is not final, failure is not fatal; it is the courage to continue that counts. — Winston Churchill

The fuselage on its wheels — working on the turtledeck.

Perhaps these quotes are a little dramatic in their relevance to building an airplane, unless perhaps you were the Wright Brothers building the first airplanes or perhaps you're a member of the Zenith 601 XL Build project team and you have just spent the last six weeks installing the seat and baggage compartment structure within the fuselage.

Yes, at times it did appear as though the end of certain tasks were far off in the future. But we as a team have persevered. It has been almost a year since we started our project, full of optimism and hope that we would be taking to the wild blue yonder in a year's time. Yes, our original anticipated completion date is now upon us and we are still a ways off from flying the wild blue yonder. What happened? Airplane building happened and what a wonderful journey it has been.

Our original group of seven members, minus one then plus one, and some dedicated volunteers have faced numerous challenges and learning opportunities that have definitely brought us all closer together over the last year. It all began with Jack Dueck's vision to gather a group of people as an EAA Chapter 1410 initiative to introduce the idea that we could build an airplane. What a preposterous idea! Who builds their own airplane? Well Jack does, and he has built a few airplanes in his day.

How do you turn a vision and perseverance into an airplane? With a group of energetic and enthusiastic people that bring labour, initiative, commitment, knowledge, and finances to the act of building an airplane. Our group is a diverse gathering of experienced builders, pilots, nonpilots, young, old, partners, and volunteers. Our youngest participant, Lucy, is 11 years old and our oldest is Jack, with an age spread of somewhere around 70 years. That's diversity!

In addition to our vested partners, we are very fortunate to have some dedicated volunteers who show up on a regular basis to help. These volunteers include Doug Eaglesham, an EAA Chapter 1410 guru on almost everything, Ron Gardner, who has the tools that Jack doesn't, Lucy Barlow, the 11-year-old, who is smart, keen, enthusiastic, and someone to tease, and our latest participant being Ken Martin, an experienced metal worker. How fortunate we are to have this talented group helping out!

Our vested partners and members of EAA Chapter 1410 are Jack Dueck, Debra Dueck, Vance Lucas, Kent Barlow, Sukhman Singh, Ethan Chan, and Kelvin Downs.

Members of the group having a busy day.

Lao Tzu suggests that every journey begins with a single step. We as a group took this advice seriously and undertook some fairly detailed project planning, which included a set of bylaws, cost estimates, schedules, regular financial reports, effort hour tracking, etc. We understood that having a plan is one of the most important steps to staying on track and eliminating any misunderstandings by the members.

From those early beginnings, we as a group we have become a close and cohesive family that looks forward to gathering every Saturday to build an airplane and to socialize over beers after a hard day’s work. What more could one ask for? Our socializing and friendships have become a very important aspect of the building process, but I am sure that many of you dedicated builders are curious about the airplane. What progress have we made? Are there any lessons we can pass on?

Our building started with a Zenith 601 XL kit that had been started but stalled for a number of years. Although the work had been done well, a fairly major modification was needed to the wings, centre spar, and fuselage as defined by service bulletins associated with a required upgrade in order to comply with FAA and EU safety concerns. As a result, our earliest tasks involved reviewing the work that had been done and then disassembling and reassembling with the required modifications. Although somewhat time-consuming, we persevered and all modifications were completed.

A rebuilt wing.

Those who have been involved in building an airplane can appreciate that there are many decisions and choices made along the way. One of the early decisions we made was to change out the Lycoming engine that we received as part of the original purchase for a lighter, more efficient Rotax 912 engine. We were able to source a used Rotax 912, and very soon after we were able to sell the Lycoming, resulting in a significant reduction of almost 100 pounds in weight. Some choices are tougher than others — especially ones regarding effort and spending — but in the case of a different engine, it was an easy decision to make.

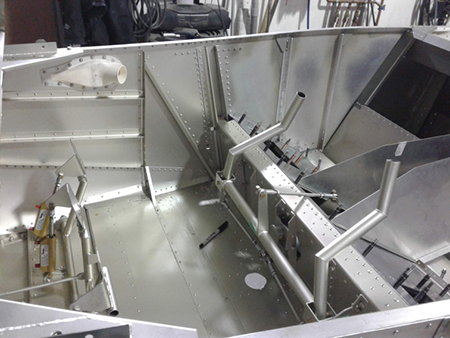

Over the past nine or 10 months since making some early decisions on engines, upgrades, becoming familiar with drawings, parts, and building processes, we have continued to make progress. Wings, ailerons, flaps, stabilizer, elevators, tail rudder are now complete. We have spent a significant amount of time (probably close to five months) on the fuselage, aligning, installing centre spars, flight controls, seat, baggage supports, etc. Our latest progress has been installing the landing gear, engine, and fitting of the stabilizer and tail rudder. It is definitely starting to look like an airplane.

Cockpit well.

So now that we are at the exciting stage of seeing all the parts and pieces starting to fit together, we have been warned by Jack many times that when you think that you are 80 percent done, there is still 80 percent left to go. The work becomes more detailed and takes more time. But we are not deterred, we will persevere.

Our next most immediate steps are continuing with engine installation. Doug Eaglesham has been a big help. We have also begun installing the top skin and fitting of the canopy components. While trial-fitting the canopy components, we discovered that our upper longerons had been reversed at the very early stages. Oh no! Only a minor setback, however; the longerons are being replaced with only minor rework. All part of building an airplane, we are told.

We are currently in the process of researching and making decisions on the avionics. We have been fortunate to purchase some Dynon Skyview screens and autopilot components that EAA Chapter 1410 member Nico Meijer made available to us from his recent upgrades. Thank you, Nico! Decisions that we still need to make are on the engine monitoring system, which will most likely be a Dynon EMS that integrates with the Skyview system. Other components such as radio, transponder, electrical distribution, and panel layout are still being researched.

We have ordered our upholstery and have been reviewing some paint schemes. Upholstery and paint discussions sound very close to flying. So of course, the most important question on everyone's mind is when do we fly? If all goes as planned, and why shouldn't it, we will start flying our 25 hours for certification by July (yes, 2020).

But before we fly, there are some additional considerations beyond finishing the airplane. These considerations are the establishment of a flying club, hangar space, and recruiting new flying club members. We have begun drafting the bylaws and cost estimates for operating the aircraft. In the meantime, some members of our group are preparing to be future pilots of our airplane by taking ground school training in anticipation of the build completion. The end and the beginning of our journey are in sight.

Perhaps this project will encourage and inspire other groups within our chapter, and perhaps even other EAA chapters, to take on future projects. We will continue to post future updates of our progress on our new chapter website. Stay tuned.

Unlike many of us who learned to fly and then took a hiatus while we built an aircraft, Kelvin intends to complete the aircraft and then learn to fly in it. Smart move, Kelvin. — Ed.