Seen Around Sun ’n Fun 2016

By J. Davis, EAA 588164, Appin, Ontario

Sonex, LTD unveils the “Model B” Sonex and Waiex editions. Modifications to the original designs are numerous and include:

- More Room and Comfort - The cabin area has been redesigned to provide more space.

- More Panel Space - The instrument panel has increased in size and can now fit dual-screen 8.5-inch glass electronic flight instrument system (EFIS) displays.

- More Fuel - New fuel tank now holds 20 USG, an increase of 4 gallons.

- More Engine Choices - Sonex is now providing engine mounts for a variety of new engine choices including UL Power and Rotax.

- More Standard Features, Quicker Build Time - Fully assembled spars and all machined angle components are now included in the kit.

Other features of note include a horizontally split prefitted cowl, hydraulic brakes, electric flaps, and centre “Y” control stick.

Sonex will be offering “B” model upgrade kits for those interested in incorporating these new design features into their original Sonex/Waiex airframe projects. More info at sonexaircraft.com

Sonex debuts its new B Model at SNF

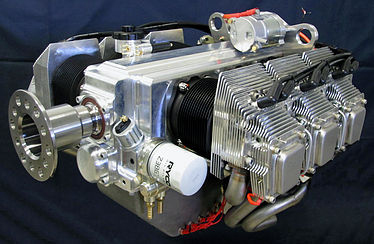

CAMit engines and parts are now available in North America. Heart of America Aviation, located in Kansas, is the new authorized CAMit Aero engine dealer. For those unfamiliar with the CAMit story, Ian Bent, current CEO of CAMit Aero, was the chief engineer during the development of the Australian Jabiru aircraft engines. Over the years, as some Jabiru engines illustrated poor or lacking design issues, Mr. Bent took it upon himself to address and improve certain aspects of the original Jabiru engines, selling aftermarket items such as clever exhaust joint systems, external alternators, solid lifter conversions, etc. As the demand for these positive mods increased, Mr. Bent decided to manufacture complete engines. Some of the improvements include:

- Solid lifters. This may seem like a step backwards, but there’s something to be said for knowing exactly what your valve train is doing and removing some of the mystery of the pump-up leak-down hydraulic lifter cycle.

- Head material. The original Jabiru head material had very little margin at high CHTs, actually starting to deform around the head bolt washers. This new alloy addresses this issue.

- Flywheel assembly and attachment bolts. Redesigned to centre-bolt to the crank (along with six outer-attachment bolts), flywheel bolt breakage should now be eliminated.

- Improved crankcase through bolt design. Eliminates the “fretting” that has happened to some original engines

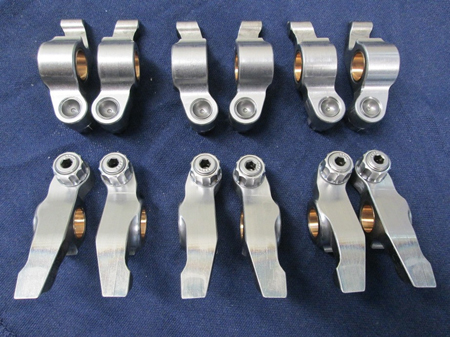

Many other redesigns and modifications include: rounder cylinder bores and upgraded rings, improved rocker arm geometry, proper piston orientation, under-piston oil-spray cooling jets, external 40-amp alternator, and more.

CAMit rocker arm kit for Jab 3300

3-into-1 exhaust joint-sealing kit

CAMit also supplies new 2200 and 3300 engines as well as overhauled/zero-timed.

New 3300 CAMit engine

For more information about the CAMit Aero engines, click here.

The famous Red Bull Air Race team set up a demonstration course at SNF this year.

Red Bull Air Race demo at SnF

Kirby Chambliss and Michael Goulian thrilled air show spectators with their display of piloting skills as they raced through the course, knife-edging through the 80-foot pylons. I got a close look at one of those 25-meter pylons as well as the inflation system. Should one of these pylons be clipped and deflated during a race, the ground crew can usually get it repaired or totally replaced within 10-15 minutes. Pretty impressive! See the season race schedule at redbullairrace.com

One of the inflatable pylons that mark the course

The pneumatic system used to keep the pylons inflated

Red Bull staff was there to demonstrate how the pylons were repaired when they are damaged during competition. It was possible to go inside the demo pylon through a zippered access slit near the base. We were told how the material is constructed to tear easily on contact with an aircraft and to propagate that tear around the circumference, which makes it easy to replace.

Gaetan Gagnon listens to presentation from Red Bull pylon team member

The pylons are constructed in nine stages, and each section of the cone is connected to its neighbours with a zipper. When a section is torn, it splits wide open, the pylon collapses and the team rushes in to replace the damaged section by unzipping it and zipping in a new section. Since the Red Bull Air Races are often over water, the teams are standing by on three fast air gate boats, ready to repair pylons the moment they are torn.

You really get a feeling for how massive these pylons are when you are standing inside. This photo of my friend Gaetan and his wife, Carole, give you a good impression of how big they are.

Like being in a gymnasium.

This is the view straight up, 80 feet!

Each pylon is 25 metres high, 5 metres across at the base, and only 75 centimetres across at the tip. An electronic control unit attempts to maintain a minimum pressure inside the pylon and, if it is unable to, it shuts down the inflation system, allowing the repair team to get on with their work. The material is specially made for these pylons, and the upper stages are very light and soft.

There are five members of an air gate boat—two to step inside and manage the inflation system, two to remove and replace the damaged part, and one to verify that the pylon is safe for the next pilot in the air races. The pylon repair is often done in under two minutes—a phenomenal achievement.