Some features are currently unavailable due to technical difficulties. We’re actively working to fix the issue. Thank you for your patience.

The EAA website is currently undergoing maintenance. Portions of the website, including membership login, join, renewal, shopping, and AirVenture ticketing may be unavailable at that time. We apologize for any inconvenience.

Your browser is not compatible with this website. Preferred browsers: Google Chrome, FireFox, or Microsoft Edge

Click here to upgrade to a newer version of Internet Explorer or Microsoft Edge.

Click here to upgrade to a newer version of Internet Explorer or Microsoft Edge.

Cookies are required for this site to operate correctly. Please enable cookies in your browser.

The Sky Has No Limits

Enthusiasts around the world share your same burning passion for aviation, a collective obsession that’s at the beating heart of EAA.Found in the Field

By Vic Syracuse, EAA 180848, Technical Counselor/Flight Advisor

-

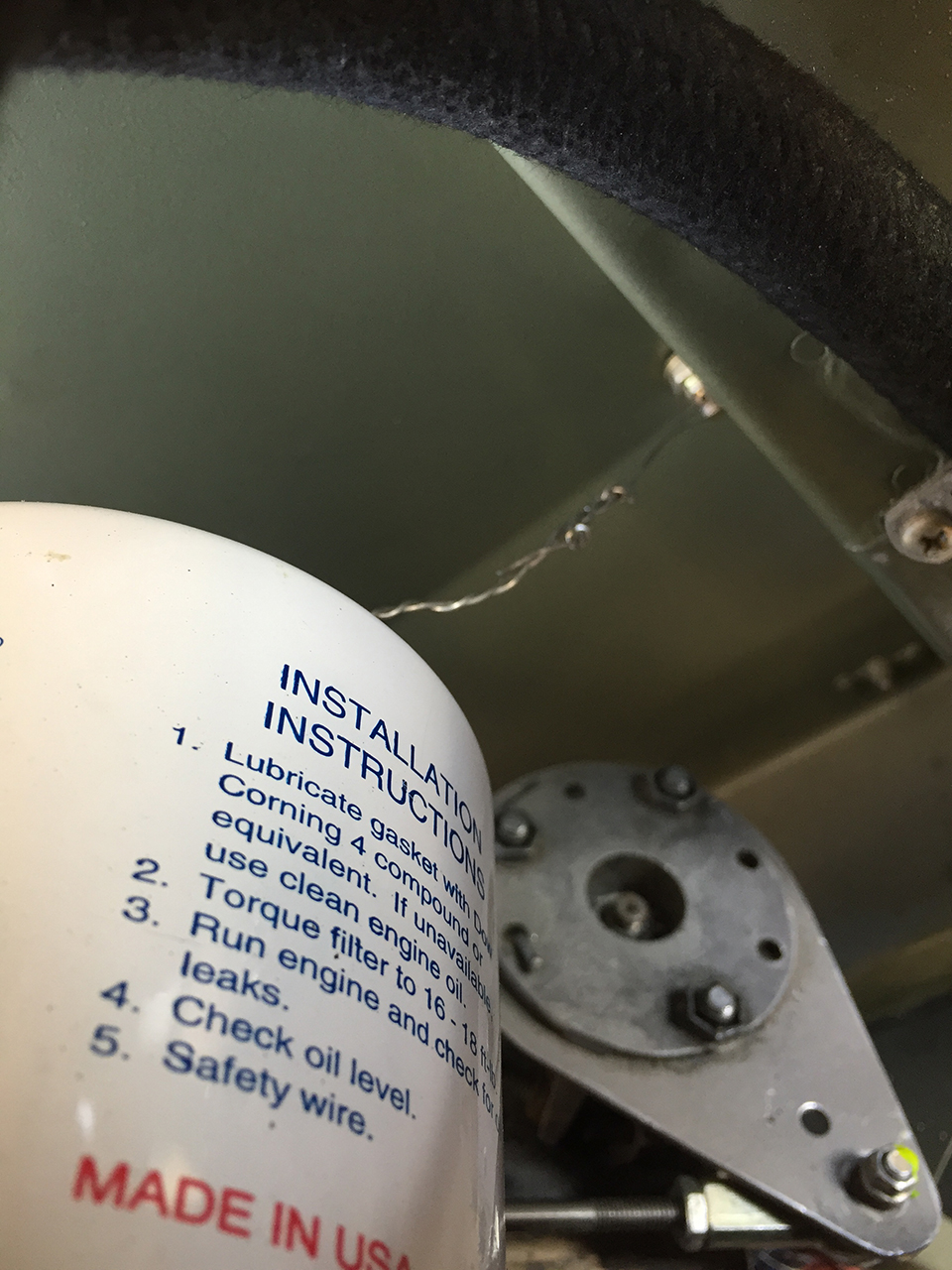

Recently I inspected an aircraft that had the oil filter safety wired to the firewall. That was definitely a no-go as there was movement between the firewall and the engine. In fact, in this particular case it was safety wired such that the movement would have loosened the oil filter. Safety wire should always be used between the object being safetied and another location on the same piece that is fixed. -

Here’s a picture of the vertical fin forward attach point on an RV-7 that had been flying for seven years. Clearly, the rivets are not set properly. A good rule of thumb is that the rivet should be approximately half the diameter in height and 1-1/2 times the diameter in width once it is set. In this case, these can easily be rectified in a few minutes with a rivet gun and a bucking bar. They should have been caught during the airworthiness inspection and for sure on the subsequent condition inspections. -

In the really poor riveting category, here is a picture of the rear spar on an RV viewed from the inside. The rivets are holding the aileron bracket to the spar, clearly a high-stress area. In fact, Van’s Aircraft has issued a service bulletin requiring inspection of this area prior to further flight. In this case, the condition inspection was signed off three months after the service bulletin was published. -

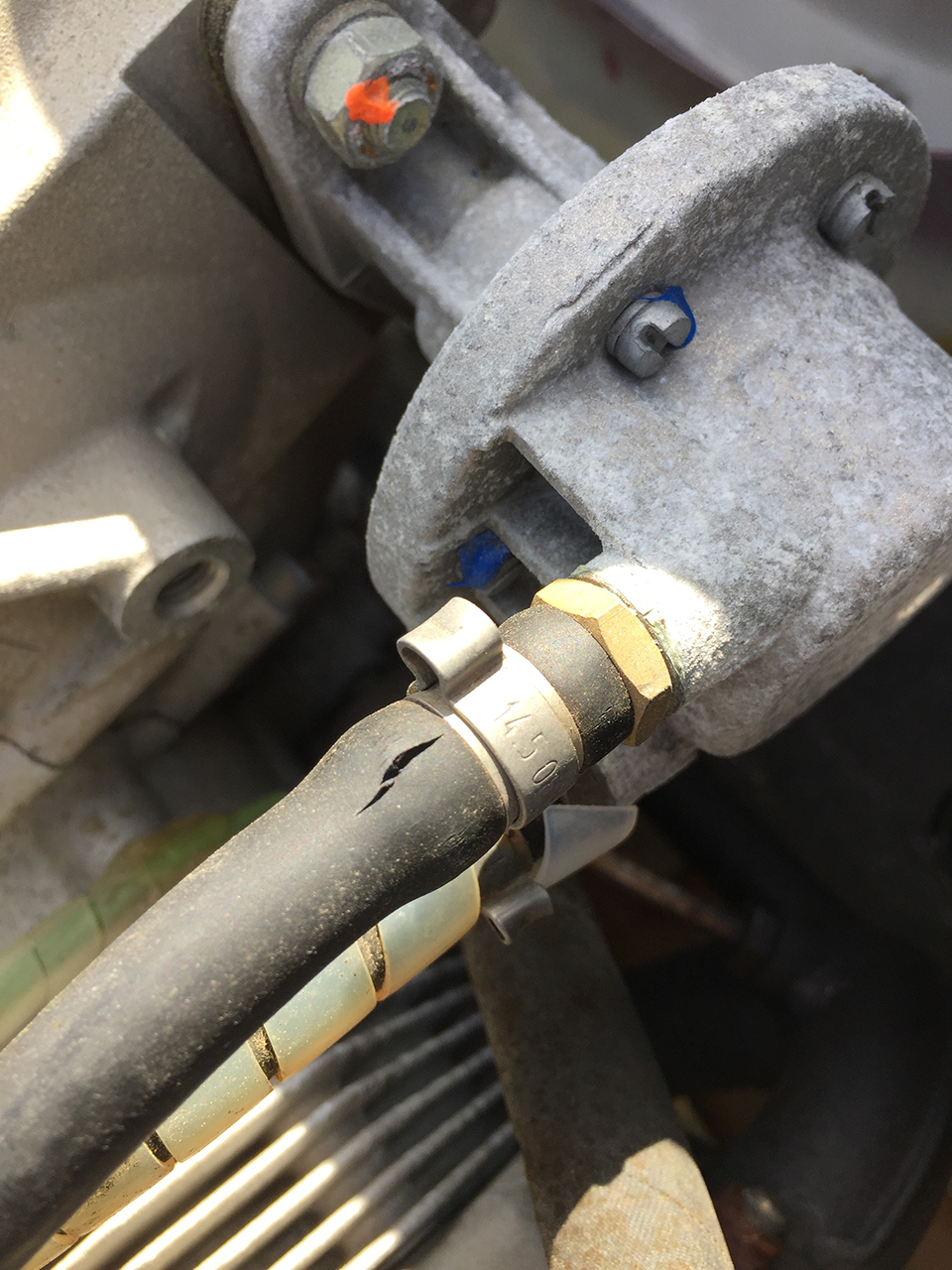

Airplanes typically have hoses to deliver fuel and oil to the engine. Many of the hoses have a useful life to them. At the very least, airplanes that have sat for a long time, especially those that sit outside in a harsh environment, should be thoroughly checked prior to flight. In this case, the airplane had sat outside for almost a year in a hot and humid environment. While engine run-up was seemingly done without any problems, a thorough prebuy inspection discovered this crack in the inlet hose to the fuel pump. A potential loss of power during takeoff was prevented. -

Ever wonder why the heater doesn’t seem to be working? Here’s an example of SCAT tubing that was installed with a very sharp bend in it. Eventually it failed and collapsed, preventing the flow of air to the heat muff and depriving the cabin of hot air.

Recent Articles

From the DAR Side

February 27, 2018

2017 Spirit of Flight Award Winner

August 25, 2017

FAA Experimental Fatal Accident Dashboard

August 22, 2017

Technical Counselor, Flight Advisor Forms Go Electronic, AirVenture, and Privatization

August 22, 2017

Program Updates – Please Read

May 15, 2017

To provide a better user experience, EAA uses cookies. To review EAA's data privacy policy or adjust your privacy settings please visit: Data and Privacy Policy.