Apollo Program Workers Were ‘In it For the Long Run’

By Barbara A. Schmitz

July 27, 2017 - Those who worked behind the scenes to design and build the Apollo spacecraft cherished and celebrated their successes, and vowed to learn from their failures.

John Boynton, of Houston, worked as a mission engineer, planning lunar missions. He started in 1960, when less than 200 people were working on the project, and said there was only one time he cried: the day Neil Armstrong first stepped off the lunar landing module and onto the moon.

John said he watched on the screen as Neil jumped onto the lunar surface. “I had a rush of emotion,” he recalled. “We worked our tail off continuously for nine years and we finally did it.”

Both John and Fred Peters, of Las Vegas, worked with North American Aviation, which later merged with Rockwell. Fred said they worked many long days. “The aerospace industry had the highest divorce rate of any industry in the country then,” he said. “We worked all the time and women were doing everything, including bringing up the kids.”

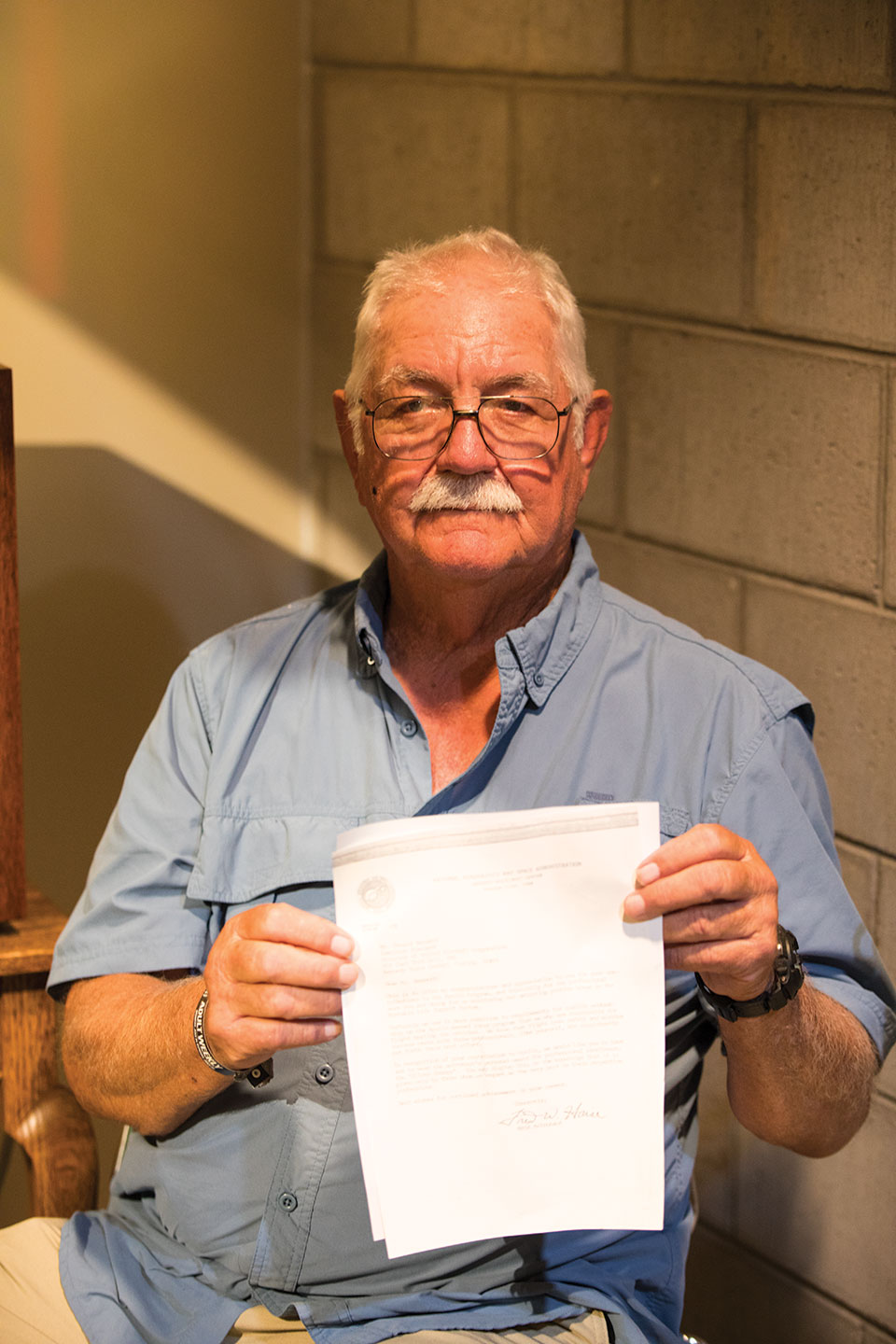

When a fire swept through the command module of Apollo 1 in 1967 during preflight, killing the three astronauts onboard, J.C. Snowden, of Sun City, Texas, said he thought the whole project would be scrapped. He worked on the launch escape system and did wind tunnel testing and launch trajectories, as well as post-flight analysis on the entry system, for North American Aviation/Rockwell.

“We were in it for the long haul,” J.C. said. “We went through a fire analysis and said nothing goes inside the vehicle that burns. Just to be sure, we tested everything, and I mean everything, with fire.”

Fred recalls working on the next spacecraft after the fire. “Although it was almost finished, we tore it down until it was just a shell and then reassembled the entire thing,” he said. It took 18 months and he remembers watching as it finally took off.

“It was the only time I got nervous, even sick to my stomach nervous,” he said. “I kept wondering if I forgot something. It really got to me.”

As the world now knows, the flight went as planned. But astronaut Wally Schirra wasn’t going to just let them rest on their laurels. “When you’re in zero gravity, things will float around if they’re not screwed down,” he said. Schirra found a little clip floating in Apollo 7, put it in plastic, and then mounted it for Fred.

But the group took their work seriously, and they did all they could to make the astronauts safe. Don Bennett, of Buford, South Carolina, was a quality engineer on the life support system. He even received the “Silver Snoopy” award for monitoring and detecting problem areas in the portable life-support system.

He said there were more than 62 companies that made parts for the Apollo capsule, and they all worked together. “Nobody was criticizing anyone else. If there was a problem, the attitude was let’s fix it and move on.”

Thirty days before a launch, you basically lived at work, he said. And if you as much as sneezed, they would quarantine you, Don said, so the launch could continue on schedule.

While they worked long hours, Don said he never felt rushed. “We had to get the job done,” he said. “We had found a new-found purpose. Everybody joined together to beat the Russians to the moon.”

William Johnston, of Neenah, Wisconsin, worked at Microswitch in Freeport, Illinois, helping to build a switch that the astronauts could easily turn on or off with their gloves on. “At the time I didn’t think I was doing anything special. I was just drawing stuff and giving it to other people who would make the parts. It was a small part of the Apollo success, but it took a lot of small parts to make it happen…”